Teaching in courses:

Research Group

MIDAS

Group leader: Edwin En-Te Hwu

MIDAS - Micro Medical Devices and Hardware Hacking Based Technologies Group

The MIDAS group pioneers out-of-box approaches to medical device development by creatively repurposing/hacking consumer electronics. We transform everyday technology like gaming consoles, DVD players, and smartphones into sophisticated scientific instruments for healthcare applications. Our unique hardware hacking methodology allows us to develop high-performance medical devices at significantly lower costs, accelerating the path from research to market.

Our expertise spans microscopy, microfluidics, biosensing, and 3D printing at the micro/nanoscale. By leveraging mass-produced consumer electronics components, we create novel solutions for medical diagnostics, drug delivery, and biomedical imaging that are both cost-effective and highly capable.

The group's vision is to democratize advanced medical technology by making it more accessible and affordable while maintaining high performance. Our work has led to multiple startups and patent licenses, demonstrating the practical impact of our research approach.

Projects

Ongoing research projects

Skin Nanotexture Biometrics for Advanced Dermatological Diagnostics

This research hacks consumer-grade PlayStation 4 Blu-ray optical components into a High-Speed Dermal Atomic Force Microscope (HS-DAFM) for advanced skin nanotexture imaging. The project integrates cutting-edge deep learning algorithms to analyze corneocyte surface topography, enabling precise, non-invasive diagnostics of skin conditions such as atopic dermatitis. This cost-effective approach demonstrates how repurposed gaming technology, combined with artificial intelligence, can revolutionize medical diagnostics by providing quantifiable assessments of skin barrier function and disease severity.

High-Resolution Large-Volume 3D Printing

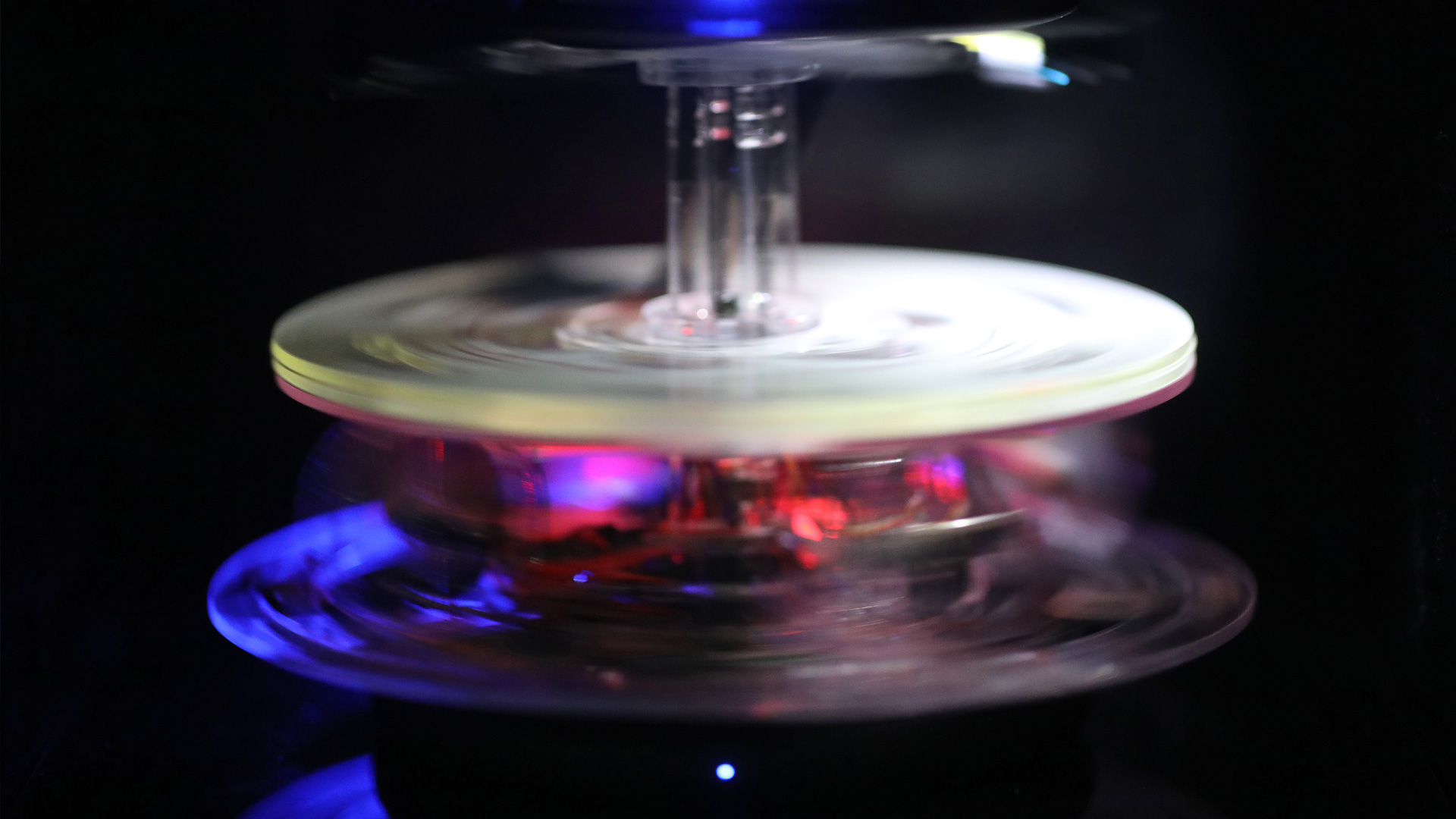

This project demonstrates a breakthrough in 3D printing technology by hacking an HD-DVD optical pickup unit (OPU) from an Xbox 360 gaming console to achieve both high resolution and large printing volume. The system achieves remarkable lateral resolution down to 385 nanometers while maintaining a substantial printing volume of 50 × 50 × 25 mm³, overcoming traditional tradeoffs between resolution and build volume. By leveraging mass-produced gaming console components costing less than $5, this approach dramatically reduces the cost compared to conventional high-resolution 3D printers while eliminating the need for complex stitching processes typically required for large-area, high-resolution printing. The system utilizes the OPU's built-in laser focusing and position sensing capabilities to enable precise photopolymerization-based 3D printing with closed-loop control, demonstrating the potential for democratizing high-resolution additive manufacturing technology.

Development of Micropumps (EMGUT project)

This project is developing the Atto Pump, the world's smallest mechanical micropump, designed to overcome the size and energy inefficiency of traditional micropumps. Utilizing technology adapted from a specific consumer electronics, the Atto Pump operates at low voltages, achieving a maximum flow rate of 636 µL/min and pressure up to 170 mBar, suitable for applications in wearables, insulin delivery, on demand drug delivery and gut sampling. Atto Pump targets markets where compact size and low energy use are critical, potentially capturing significant shares in wearable and oral biomedical devices.

Videos related to MIDAS

Group Leader

Edwin Hwu Group leader, Associate Professor Department of Health Technology etehw@dtu.dk